What You Need to Know About SMD Resistor Size

An SMD resistor is an essential passive component found in many electronic circuits and applications, used to limit current flow, limit voltage levels, and control circuit behavior. These are widely employed due to surface mount technology (SMT), which facilitates automation while increasing production quality, reliability, and high functional density.

Engineers and technologists should have an in-depth knowledge of SMD resistor types, sizes, markings, and identification methods to take full advantage of these tiny yet vital parts. This article covers these subjects.

SMD resistors are created by attaching end connection electrode bases to an alumina or ceramic substrate and firing it, to secure their connections. Next, resistive material is printed or deposited and the component is once more fired to complete its production. Resistance values are determined by length, thickness, and the material type used in their creation.

Components are then trimmed using a YIG laser before being coated with multiple layers of protective coating to protect them against mechanical damage as well as moisture ingress and other contaminants. Once complete they can either be packaged as blister rolls for use on pick and place machines or provided loose to be utilized with such devices.

Power Rating

The power rating of a resistor depends on several factors, including its physical size and construction.

Larger resistors generally tend to have higher power ratings due to having more surface area for dissipating heat. This is why it is a component in determining surface mount resistor size, among other factors. Conversely, smaller resistors tend to dissipate heat less effectively so have lower ratings; additionally, the temperature coefficient may have an impact on its power rating as well.

SMD resistors come in standard sizes that are indicated by numeric codes; for instance, 0603 stands for 0.08″ long by 0.030″ wide. This makes SMD resistors an excellent choice for automated PCB production and design but they may prove challenging to solder manually.

SMD resistors come in all kinds of styles and sizes, from tiny 0805 resistors to larger 2512 ones. They may come supplied on blister rolls ready for pick and place machines or soldered by hand; either way, they must be stored properly to prevent damage to them during transport and assembly.

Selecting SMD Resistors can be difficult when they’re so small. When making your selection, take into account factors like power rating, tolerance, temperature coefficient, and packaging; this will allow you to find the ideal resistor for your application.

Tolerance

Surface-mount resistors typically take the shape of small black rectangles with two shiny silver-conductive ends tacked to either end, creating tiny rectangles tipped off at either end by silver conductive edges that have even smaller size specifications.

They’re intended to sit atop printed circuit boards (PCBs) where they’re placed automatically by pick and place equipment before going through an oven to melt away their solder coating and secure their position permanently. You can click here to learn more about printed circuit boards. They’re commonly sold packaged in blister rolls for pick and place machines or they can also be supplied loose.

Surface-mount resistors are typically marked with either a three or four-digit code, which displays their resistance value. The first two digits indicate resistance values while the third can indicate multipliers.

Some manufacturers also mark SMD resistors with 1% tolerance using an alternative EIA-96 marking system which uses standard three-digit codes with short bars below them to indicate this is from the E24 series which normally contain only values up to 5% tolerances.

Trying to understand what a specific manufacturer’s three or four-digit codes mean can be challenging; to help with that process use a surface mount resistor code calculator. Be mindful that different manufacturers use various marking systems which may differ so it’s advisable to inquire with suppliers beforehand in order to receive parts with the proper tolerance requirements for your application.

Temperature Coefficient

Surface Assembly Technology has become so prevalent today that many electronic products use Surface Mount Device (SMD) components.

This method of production provides for increased manufacturing reliability and higher quality overall, including resistors of various sizes such as 1206 sheath to 0805 and smaller resistors produced using metal oxide film for temperature stability – it may even be worthwhile de-rating these resistors to further increase reliability.

To increase reliability even more it may be wise to derate SMD resistors and run them closer to their maximum rating for maximum reliability. Be sure to check the ratings for more information.

Due to their small sizes, there may not be enough space on components for traditional color codes to be displayed on them. As an alternative solution, manufacturers have implemented an EIA-96 numbering system: two or three digits represent resistance value while the last digit indicates multipliers. You can click the link: https://www.hobby-hour.com/electronics/eia96-smd-resistors.php to learn more.

Packaging

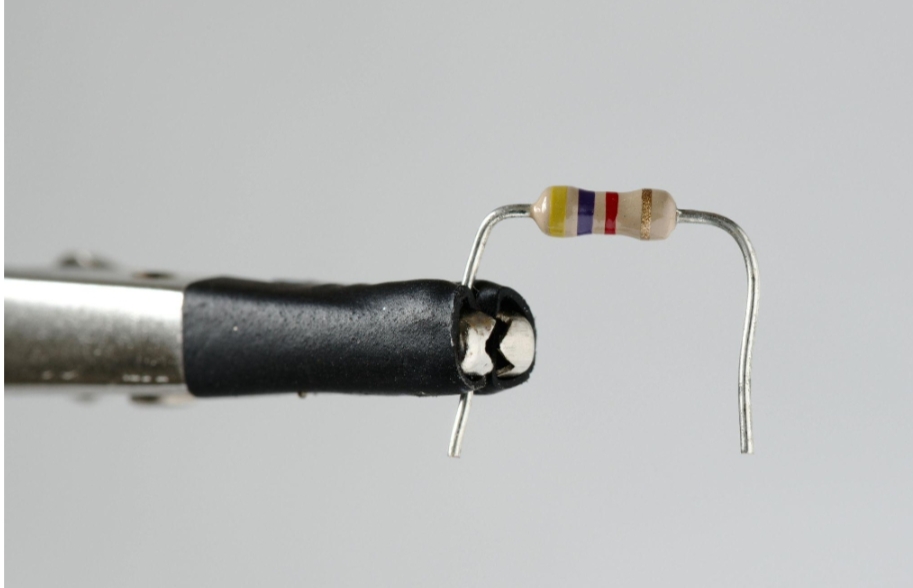

There are various package styles for SMD resistors. Axial styles exist while others feature leads that extend out either end of the main ceramic body and have metalized ends for soldering onto printed circuit boards. An axial package’s dimensions depend on its power rating: 1/2W resistors measure 9.2mm across, while 1/4W versions come in at 6.3mm wide.

SMD resistors are typically organized into rows and columns identified by three- or four-digit codes consisting of both imperial and metric units as well as an indicator number representing pad center spacing in inches. 0201 packages measure 0.6mm by 0.3mm; these resistors are commonly found in high-density applications like mobile phones. Larger SMD resistors such as 1206 can also be found and are ideal for multiple uses.

Many SMD resistors are constructed of metal oxide film, providing a better temperature coefficient compared with older technologies like lead. Furthermore, SMD resistors have more durability and reliability compared with through-hole resistors as well as more eco-friendly packaging than their predecessors. Furthermore, SMDs are easier to work with than through-hole components which require drilling holes into a circuit board before installation; all factors that contribute to their immense popularity among modern electronic designs.